They are up to 70 meters wide and can lift a similar weight in tons, but despite their huge size, RMG cranes need to offer extremely precise mobility in order to load containers safely, securely and accurately. The latest Hübner Giessen case study reveals how targeted modernization measures can significantly improve the switching accuracy of a crane hoist.

Outdated components reduce signal quality

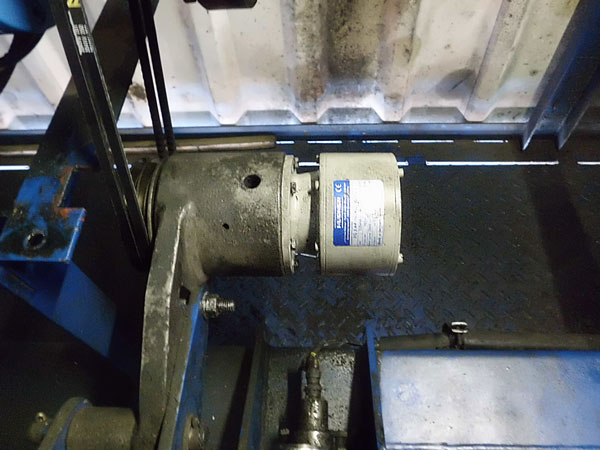

The speeds of the hoist motors of RMG cranes need to be precisely recorded and monitored to ensure smooth workflows. In older systems, mechanical components are mostly used to fulfil this purpose. The Hübner customer in this case study, for example, used a tacho generator with an additionally mounted mechanical overspeed switch. When it comes to precision and switching tolerance, however, such old components can no longer keep up with modern solutions and provide the signal quality that is possible in the present day.

A modern replacement solution from Hübner Giessen

Based on their experience from a multitude of modernization projects, the Hübner experts were able to rapidly come up with a tailor-made encoder solution using state-of-the-art technology. By replacing the old components with a compact system comprising an incremental encoder and an integrated electronic overspeed switch, this solution enables much more precise overspeed monitoring. You can read all about the modernization in detail in the case study “Hoist / Motor: Achieving much higher switching accuracy on a crane hoist with a compact incremental encoder with an additional electronic overspeed switch”.