Coil coating is a fully automated process in which rolled metal strips are given an evenly organic coating. This procedure is much more efficient than coating individual parts, but only if the coating quality is right. Our case study shows how we improved the quality of the coil coating for a leading steel manufacturer.

Even rotation over long distances

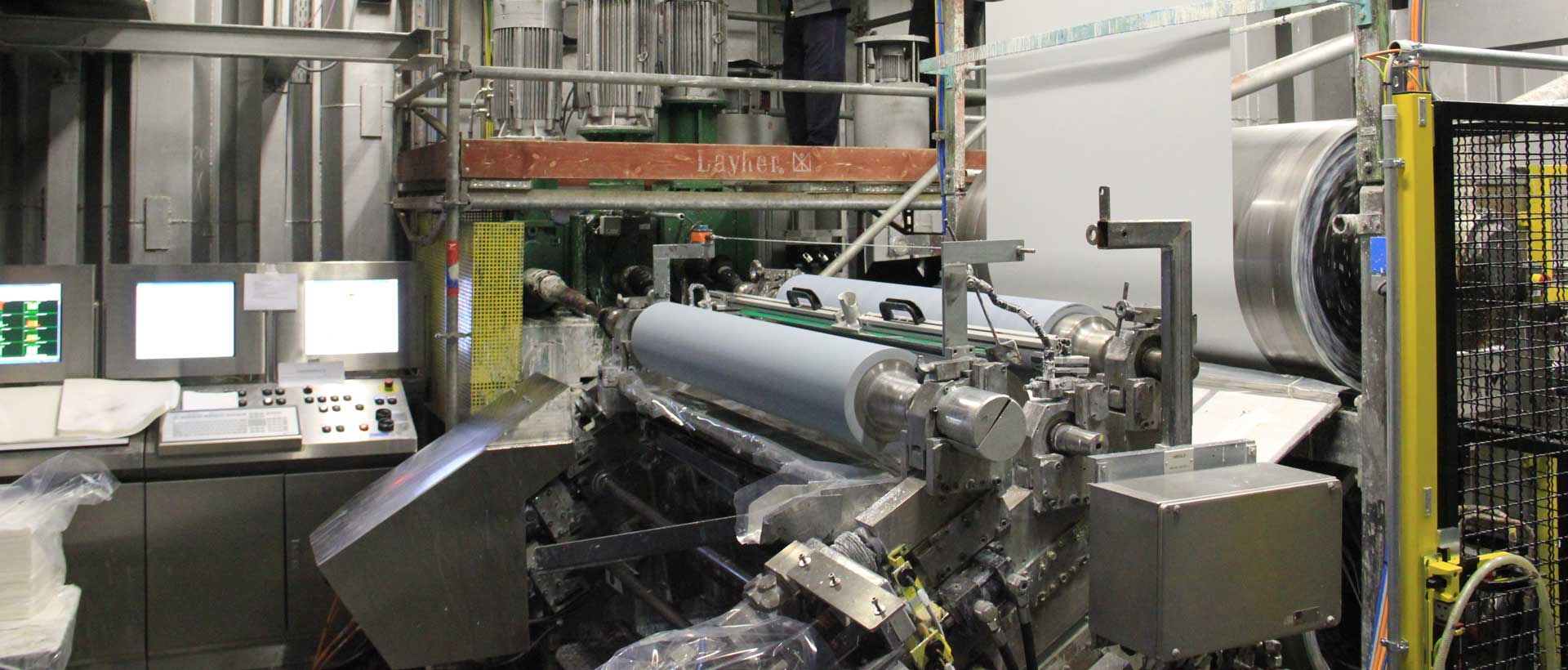

When it comes to coating steel or stainless steel strips, the untreated coils first need to be unrolled. The strips are then coated in a rolling procedure, which sometimes involves applying several layers, depending on the type of coating required. After it has been dried and cooled, the coated strip is rolled back into a coil. To achieve optimal coating quality, the coating rolls must rotate extremely evenly throughout the entire process. If the coating or sealing is uneven, entire coils may be rejected.

Time-saving modernization by Hübner Giessen

A leading steel manufacturer contracted us to modernize the motor used in its coil coating plant, hoping to improve the coating quality by converting from analog to digital speed control. Given that the plant is classified as a potentially explosive gas atmosphere, the new solution needed to be ATEX- and IECEx-certified. Our experts handled all stages of the modernization process, from the initial measurements right through to installation. You can find out which digital Ex-protection encoder they chose, why it is particularly durable and how it was successfully mounted in the case study “Coil coating / Motor: improved coating quality in coil coating with the new Ex-protection encoder”.