Systems operators in many industries are required to ensure that the systems used do not become a danger to humans, the environment and the machinery itself. This requirement is stipulated in functional safety standards and so-called SIL (safety integrity level) standards. Based on the example of a test stand, our case study demonstrates how SIL-certified safety components can also be easily integrated into systems at a later point in time.

Protection thanks to functional safety

Systems and machines can never be operated with no risk of malfunction or accidents whatsoever. Nevertheless, safety equipment can be used to significantly reduce the residual risk of danger to humans, the environment and machinery. One example of such protective systems is overspeed switches, which monitor whether a motor speed is within a defined range. When these switches are SIL-certified, they are also permitted to be used in functional safety applications.

A safety solution from a single source by Hübner Giessen

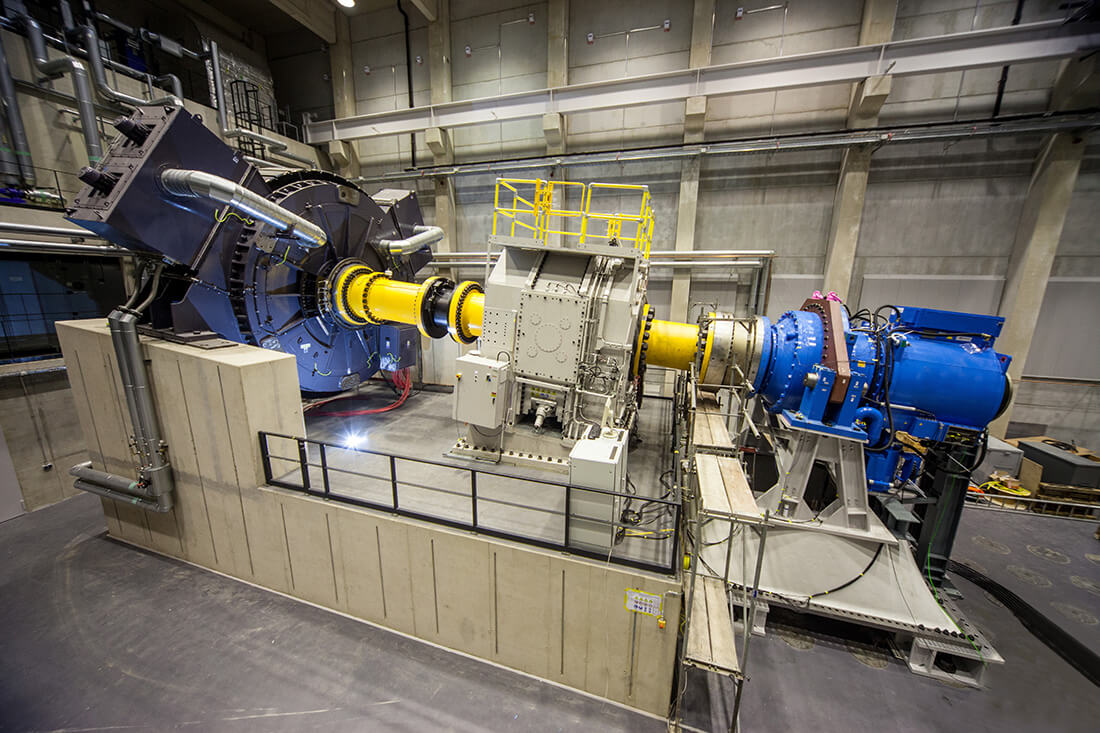

In this case, non-SIL-certified speed monitoring in a test stand needed to be replaced by a new SIL-certified system that could be combined with a mounting solution that was also SIL-certified to increase the operating safety of the test stand. Our experts came up with a complete solution from a single source featuring several products from our portfolio, namely an overspeed switch, a safety adapter shaft, a safety torque bracket and SIL-certified switching outputs. You can take a detailed look at our encoder and mounting solution by reading our case study: “Test stand / Motor: Retrofitted SIL certified encoder and mounting solution on a test stand”.