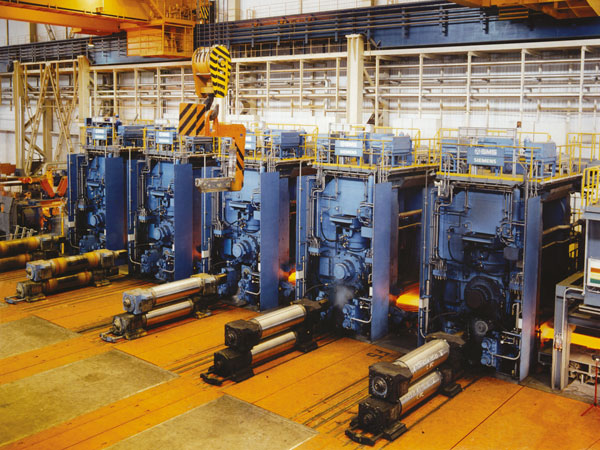

In rolling mills, every micrometer counts, and the precise setting of the roll gap is what mainly determines the thickness and quality of the rolled strip. Nowadays, conventional mechanical cam limit switches often fail to still achieve the required accuracy. At the same time, wear and complex setting adjustments make operating and servicing the system more and more expensive. In our case study, we show how modern electronic position switches increase precision and noticeably reduce operating costs.

High complexity, low precision

Mechanical cam limit switches on roll screw-downs are susceptible to wear and backlash, which, in turn, lead to uneven strip thicknesses, reworking or, in the worst-case scenario, rolling scrap. A particularly critical factor is that precisely setting the roll gap is a time-consuming process that requires frequent interruptions to production, yet still fails to always achieve the desired accuracy. In practice, this means higher costs and lower system availability – a risk that can be easily averted with modern position switches.

Retrofitting with added benefits by Hübner Giessen

A customer who was unhappy with the existing mechanical cam limit switch on their roll screw-down contracted us to find a more precise and cost-effective solution with spare parts that are also easier to obtain. Our chosen alternative was the ERC 40. This electronic position switch not only meets all of the customer’s requirements but also simplifies the installation of the system. You can find out more about how exactly this retrofitting works and the advantages that it offers operators by reading our case study on “Rolling mill / screw-downs: higher accuracy and lower costs by replacing mechanical cam limit switches”