Occupational safety is important, which is why we have introduced a new addition to our well-established FGH 6 encoder system solution: a made-to-measure protective cover that reliably prevents accidents caused by rotating parts.

Safely avoid hand injuries

FGH 6 incremental encoders by Hübner Giessen are often mounted on the unused shaft end by means of an isolated adapter flange. If employees touch the rotating shaft while it is in operation, they can severely injure their hands. To minimize this accident risk, we have developed a made-to-measure protective cover for FGH 6 installations. It is available in three sizes and is suitable for adapter shafts with a diameter of up to 280 mm.

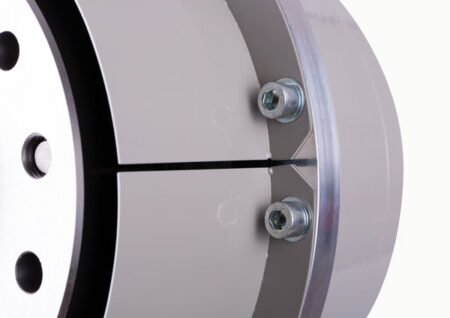

Simple screw fastening

Retrofitting existing installations with the new protective cover is a particularly straightforward process that only involves a few steps and does not require mounted FGH 6 incremental encoders to be dismantled. First, a fastening plate is screwed onto the encoder. The two halves of the protective cover are then screwed together and onto the fastening plate.

Find out more about the new protective cover in our flyer now.